Tool and Die

Unlocking the Power of Tool and Die: An In-Depth Look

Our capabilities:

FAQ Tool and Die

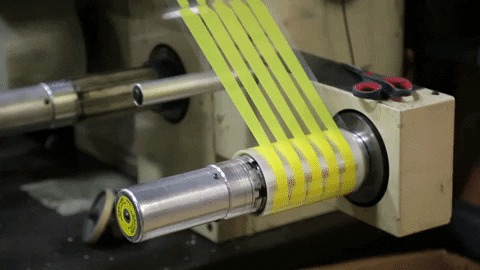

Tool and Die is a technique used to create metal molds and forms that are used in shaping and forming metal products. It is a combination of both tools and dies that work together to produce the final product. The tool is used to shape the metal, and the die is used to hold the metal in place as it is being formed.

The tool is typically made from steel and is designed to apply force to the metal product. The die, on the other hand, is usually made from a harder material such as carbide or tungsten, and is designed to withstand the pressure applied by the tool. Together, the tool and die form a system that allows manufacturers to create precision metal parts quickly and efficiently.

-

Design: The first step in creating a Tool and Die is to design the tool and die. This involves creating a detailed drawing of the tool and die, including all the dimensions, features, and specifications.

-

Prototype: Once the design is complete, a prototype of the Tool and Die is created. This is done to ensure that the design is correct and that the tool and die will work as intended.

-

Production: After the prototype has been tested and approved, the Tool and Die is then produced using specialized machinery and tools.

-

Testing: Once the Tool and Die has been produced, it is then tested to ensure that it is functioning correctly and producing parts that meet the specifications.

-

Automotive: Tool and Die is used in the automotive industry to create parts for cars, trucks, and other vehicles.

-

Aerospace: Tool and Die is used in the aerospace industry to create parts for airplanes, helicopters, and other aircraft.

-

Defense: Tool and Die is used in the defense industry to create parts for weapons and military equipment.

-

Consumer Goods: Tool and Die is also used in the production of consumer goods such as appliances, electronics, and toys.

-

Medical Devices: The precision and accuracy of Tool and Die make it ideal for use in the production of medical devices such as implants and surgical instruments.

The process of creating a Tool and Die involves several steps including design, prototype, production, and testing.