Absolute Laser & Manufacturing

- Amplify the characteristics and beauty of metal goods All metallic materials can be treated. Attainable on many kinds of parts, including intricate ones Professional engineers to assist you in determining the appropriate application solution for all project sizes.

Contact Us

ABSOLUTE LASER & MANUFACTURING

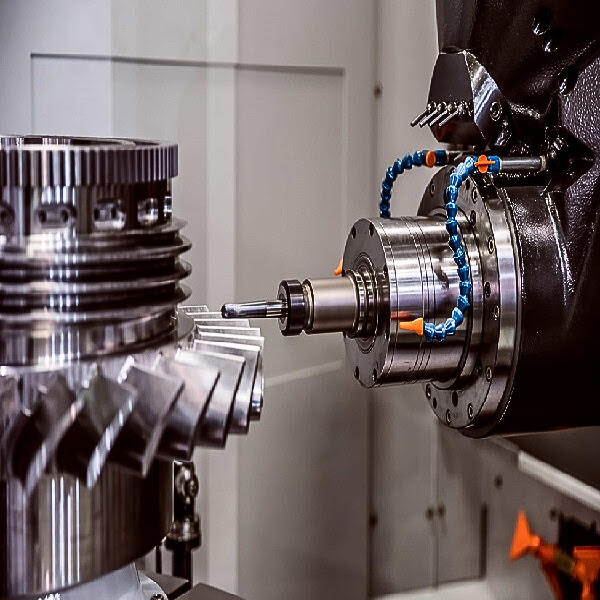

At ABSOLUTE LASER & MANUFACTURING, we provide a full range of services. Our skilled staff collaborates with our clients at every step, from design assistance to completion, to guarantee that we provide a high-caliber final product.

We can provide metal finishing as part of this. We can identify the best solutions for your project, always staying within project timelines, regardless of the needs of the application or the specifications of your material. ABSOLUTE LASER & MANUFACTURING’ exceptional reputation in the business has been made possible by this degree of service and dedication to quality.

Powder Coating

Products can be powder-coated for a vibrant, protective finish. By using the international RAL color chart, we can powder coat in any color. It is possible to achieve both glossy and matte finishes, with varying grade finishes to meet application needs and financial constraints.

Wet Painting

For the purpose of finishing various kinds of metal components, spray-applied wet liquid paint comes in a variety of colors. To make sure your product is appropriate for its use, we can adapt if it needs a specialized paint.

Plating

To give your product the ideal metal coating, we provide electroplating. Electroplating can be done to suit aesthetic needs or improve the component’s characteristics, such as its resistance to abrasion and corrosion. Hydrolysis is the method used to do this.

Galvanising

For bigger parts and components, ABSOLUTE LASER & MANUFACTURING may offer hot dip galvanizing, which coats steel and iron items in numerous layers of protective zinc. For full coating efficiency, spin galvanizing is also an option for protecting smaller parts like screws, bolts, and nuts.

Chemical Blacking

Chemical blacking is the process of using a chemical reaction to give ferrous objects a black finish. Components that are blackened satisfy aesthetic standards, reduce light reflection, and offer better corrosion protection. Small components are suited for chemical blacking.

Anodising

Anodizing is an electrochemical procedure that provides an all-inclusive coating solution by thickening the natural oxide layer on aluminum items. Anodizing is finished for improved corrosion and abrasion resistance as well as aesthetic purposes.